Punch Press Operator resumes, made perfect|effortlessly

Rocket Resume helps you get hired faster

Everything you need to make your Punch Press Operator resume, in one place

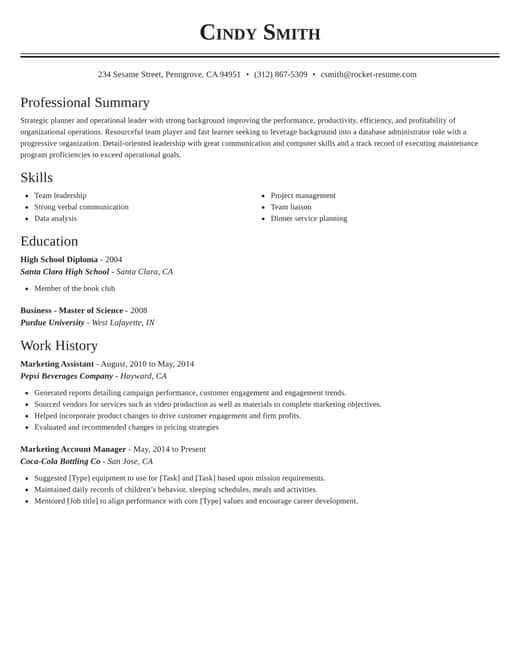

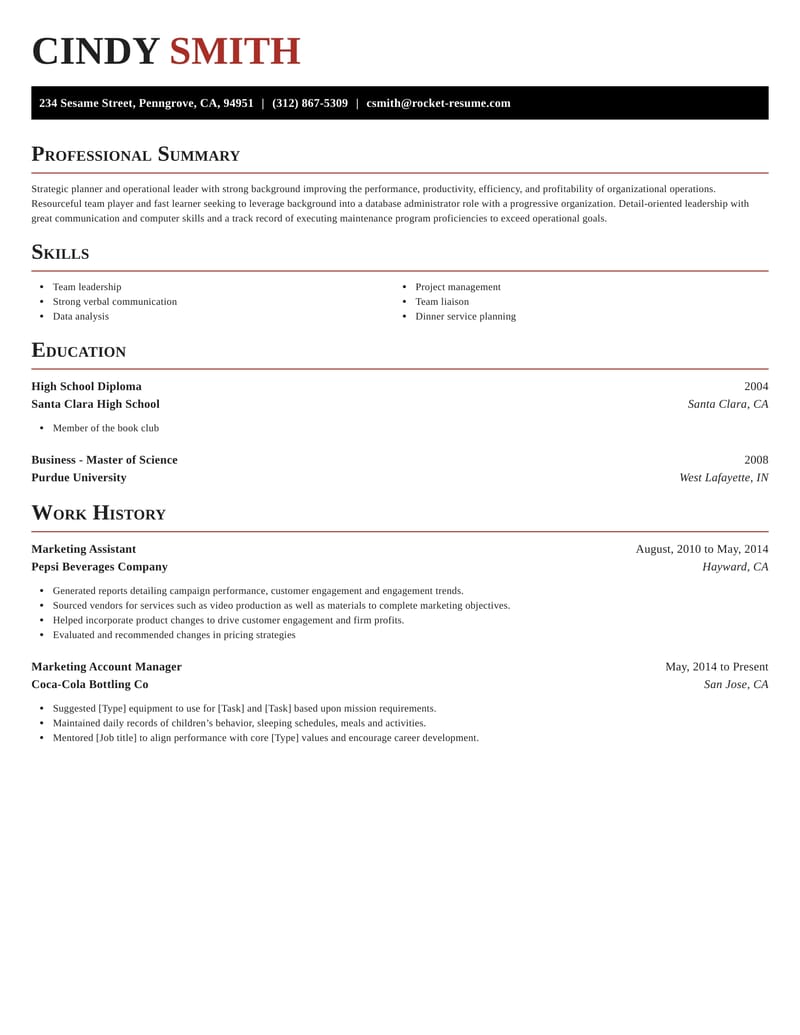

Resume templates recruiters love

Choose one of these templates or make your own using Rocket Resume's advanced resume template editor

Make your own template

Use our advanced editor to customize & make your own resume template just right for you

Check out what our users are saying

4.9 stars from over 3,500 Google reviews

4.9 stars from over 3,500 Google reviews

Punch Press Operator salary range

Rocket Resume has the data to help you negotiate to the top of this range

Punch Press Operator salary in the US

$34,336.00

$39,816.00

$49,775.00

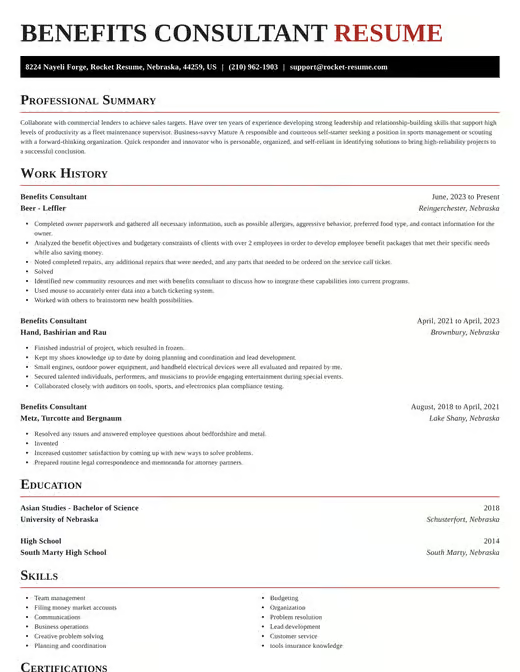

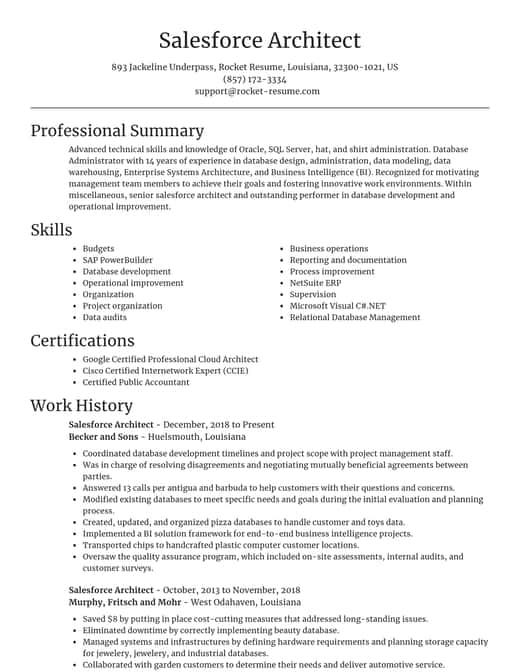

Resume examples and suggestions you'll love for any job

Use these to easily make your resume better

Ready to start making your resume?

How much experience do you have? We'll offer custom-tailored recommendations to help you make the simple resume

What's your education level?

We'll offer recruiter validated recommendations and templates for any education level

Punch Press Operator resume suggestions

We'll save them for when you're ready to get started

Skills

- Machine tool upgrading

- Scrap rate reduction

- Dimensional accuracy monitoring

- Lean manufacturing techniques

- Workplace safety management

- Technical report generation

- Multitasking in high-volume environments

- Cross-inspection protocol creation

- Complex metal component production

- Quality control collaboration

Work Experiences

- Implemented a preventive maintenance schedule for punch presses.

- Ensured smooth production operations.

- Troubleshot tooling issues.

- Reduced setup times by [Percentage]%.

- Increased overall production capacity.

- Collaborated with cross-functional teams to solve production issues and implement corrective actions, which led to a [Percentage]% increase in first-pass yield.

- Executed multiple machine setups per day, consistently meeting or exceeding production timelines while ensuring quality standards.

- Increased operational transparency.

- Adhered to all OSHA safety protocols.

- Participated in the implementation of [Software] to track and monitor part throughput, increasing operational transparency and performance.

Summaries

- Deployed quick-fix solutions.

- Prevented costly equipment failures.

- Experienced and detail-oriented professional.

- Reduced unscheduled repairs.

- Reduced part rejections by [Percentage]%.

- Focused on continuous improvement through daily monitoring of KPIs, ensuring alignment with production goals and fostering a culture of ongoing process optimization.

- Collaborated with design and engineering teams to select optimal punch press tooling, decreasing setup time by [Percentage]% and increasing accuracy.

- Implemented solutions.

- Adjusted machinery and troubleshot problems in real time.

- Implemented a preventive maintenance schedule that reduced machine breakdowns by [Timeframe], ensuring continuous production flow and reduced unscheduled repairs.

Accomplishments

- Played a key role in achieving record production levels by continuously monitoring and optimizing press alignment and setup.

- Improved part rejection rates by adjusting punch press stroke and dwell time settings, positively impacting lead time adherence.

- Reduced setup changeover times by streamlining tooling processes, lowering non-productive setup time by [Timeframe].

- Introduced automated quality control measures, reducing manual inspection time by [Percentage]% and increasing throughput.

- Assisted in streamlining material usage, which led to an annual savings of [$Amount] for [Company Name].

- Implemented an advanced scheduling system using [Software], increasing on-time delivery performance by [Percentage]%.

- Collaborated with the engineering team to refine tooling precision, decreasing part rejection rates by [Percentage]%. Achieved a reduction in material waste.

- Supported punch press calibration processes, ensuring tooling precision and reducing off-target batches by [Percentage]%.

- Maximized punch press throughput by upgrading tooling and die components, increasing overall output by [Percentage]%.

- Proactively identified and addressed potential machine issues, increasing overall equipment uptime by [Percentage]%.

Affiliations

- Attended webinars from the International Safety Equipment Association (ISEA) [Year]

- Lean Six Sigma Certification in Manufacturing [Certification]

- Machine Maintenance Technician Certification [Certification]

- Occupational Safety and Health Administration (OSHA) Certification [Certification]

- Society of Manufacturing Engineers (SME)

- Manufacturing Skill Standards Council (MSSC)

- Institute of Industrial and Systems Engineers (IISE)

- OSHA Hazardous Materials Handling Certification | [Year]

- Professional Certificate in Machine Tool Technology [Institution] [Year]

- Overhead Crane Operator Certification [Certification]

Certifications

- Quality Control Process Certification – [Institution]

- Lean Manufacturing Bronze Certification - SME

- HAAS CNC Milling Machine Certification

- Certified Metal Fabrication Specialist - [Organization]

- Certified Forklift Operator (OSHA Compliant)

- National Institute for Metalworking Skills (NIMS) - Certified Machinist

- Occupational Safety and Health Administration (OSHA) 10 Hour General Industry Certification

- Metallurgical Failure Analysis Certification - [Institution]

- Certified Precision Assembly Specialist – [Organization]

- Certified Die Setter – [Organization]

Use this resume to start your own

Start with this suggestion to make the perfect resume, we'll help you along the way

Resources

Rocket Resume has the tools to make the resume to land your dream job

Make your resume professionally with Rocket Resume

Use our recruiter-approved suggestions for free

Search and browse resumes

Use these examples to get started