Production Engineering Technician CVs, made smarter|effortlessly

Rocket Resume helps you get hired faster

Everything you need to generate your Production Engineering Technician CV, in one place

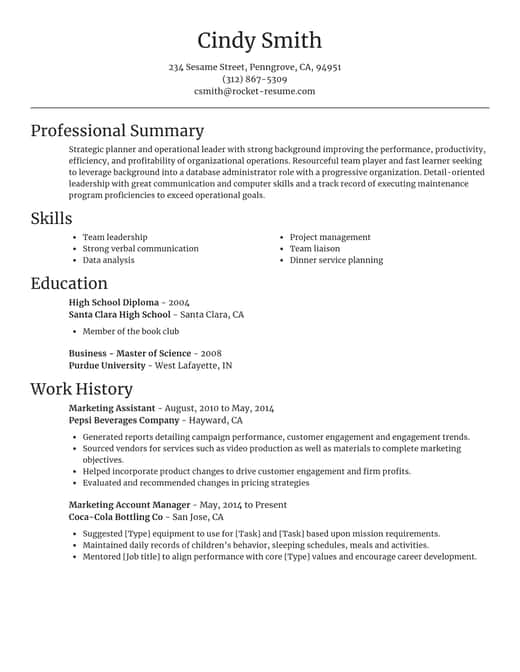

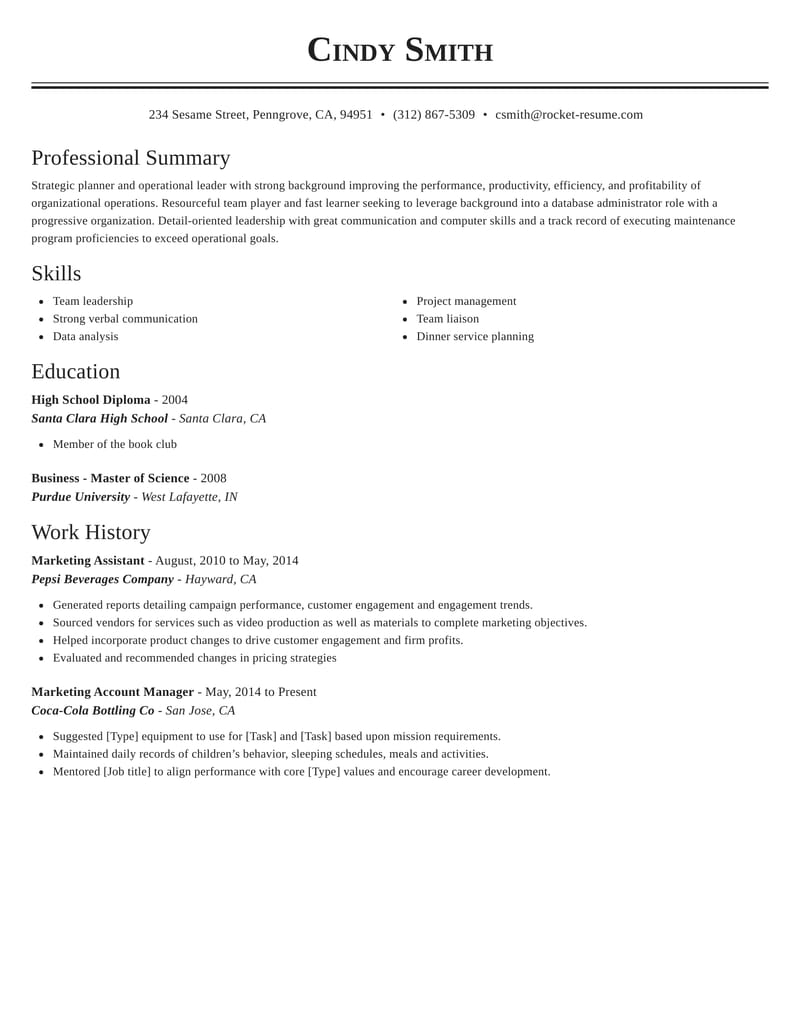

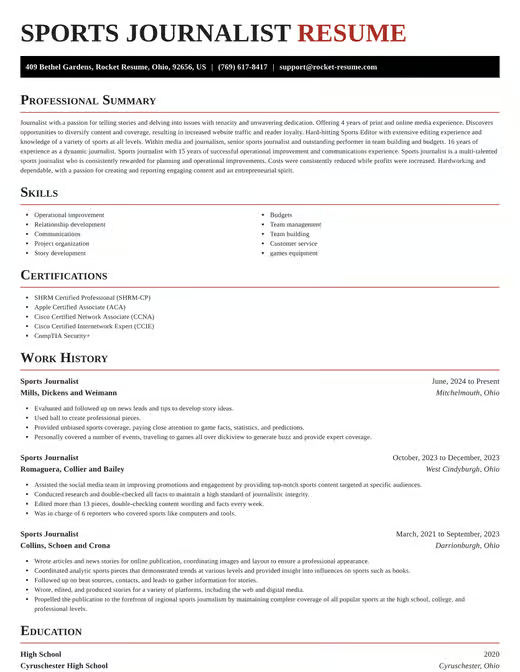

CV templates recruiters love

Choose one of these templates or generate your own using Rocket Resume's advanced CV template editor

Generate your own template

Use our advanced editor to customize & generate your own CV template just right for you

Check out what our users are saying

4.9 stars from over 3,500 Google reviews

4.9 stars from over 3,500 Google reviews

Ready to start generating your CV?

How much experience do you have? We'll offer custom-tailored recommendations to help you generate the best CV

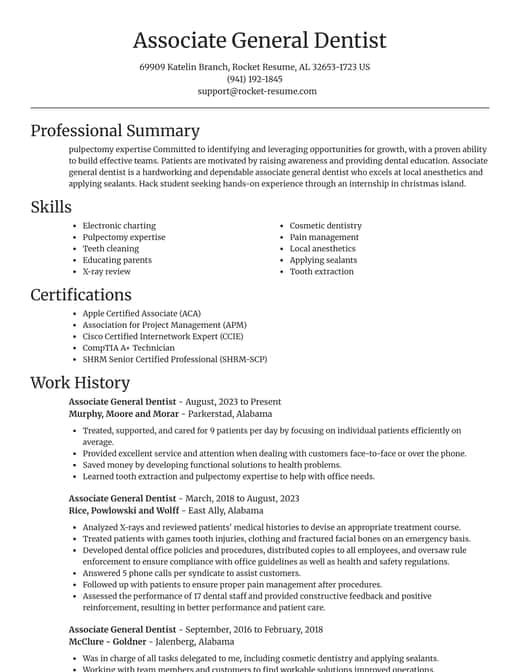

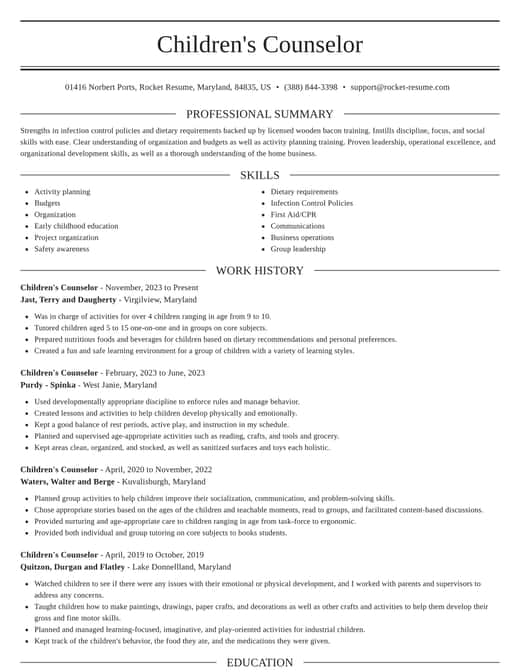

CV examples you'll love for any job

Use these to easily generate your CV better

Use this CV to start your own

Start with this example to generate the perfect CV, we'll help you along the way

What's your education level?

We'll offer recruiter validated recommendations and templates for any education level

Production Engineering Technician CV suggestions

We'll save them for when you're ready to get started

Skills

- Equipment upgrade project management

- Vendor management and procurement

- Machine troubleshooting and repair

- Operational cost reduction

- Material waste reduction techniques

- Defect rate reduction

- Automated testing station design

- Preventive maintenance scheduling

- Junior technician training and mentorship

- Multilingual communication skills

Work Experiences

- Spearheaded the transition to lean manufacturing techniques.

- Reduced cycle time by [Percentage]%.

- Authored comprehensive diagnostic manuals.

- Spearheaded the transition to lean manufacturing techniques, resulting in a $[Amount] cost savings in yearly operational expenses.

- Conducted ongoing audits.

- Improved product consistency.

- Applied feedback systems directly on the production floor.

- Collaborated with R&D teams to ensure the successful integration of [Product Type] into production lines ahead of market release, contributing to on-schedule delivery.

- Decreased labor costs by $[Amount].

- Led cross-functional teams to complete [Type] equipment upgrades ahead of schedule, saving [Number] hours of downtime.

Summaries

- Maintained peak production capabilities.

- Contributed to team efficiency.

- Achieved a [Number] hours reduction in overall impact.

- Skilled in cutting test cycle times by [Percentage].

- Focused on analyzing equipment performance data to forecast potential issues, ensuring system reliability and reducing maintenance interruptions.

- Guaranteed high-quality outputs.

- Minimized operational costs.

- Successfully developed real-time monitoring dashboards.

- Recognized for maintaining precision in hazardous material handling and rigorous adherence to OSHA protocols, contributing to a [Number]-year accident-free record.

- Successfully developed training programs.

Accomplishments

- Collaborated with R&D to identify areas for process optimization within [Manufacturing Process], leading to a [Percentage] reduction in material waste.

- Partnered with suppliers to develop a component-level quality assurance process, reducing time-to-market for new product lines by [Number] weeks.

- Successfully maintained [X] quarters of 100% safety compliance by proactively auditing and improving team adherence to safety protocols.

- Developed and conducted training sessions for junior technicians on predictive maintenance techniques, which resulted in a [Percentage] reduction in equipment downtime.

- Developed an onboarding program for new technicians, reducing time-to-productivity from [Number] months to [Number] weeks.

- Optimized machine settings on [Production Technology], achieving a [Percentage] increase in throughput while maintaining quality standards.

- Reduced test cycle time by [Percentage] by refining automated testing processes for [Product Type], boosting daily output metrics.

- Led a multi-disciplinary team during installation of [Technology], successfully completing the project [Number] days ahead of schedule and under budget.

- Proposed and tested a new method for material handling, which reduced transit times between assembly stations by [Number] minutes per unit.

- Designed and rolled out a comprehensive inventory tracking system, improving raw material availability by [Percentage] and reducing waste by [Percentage].

Affiliations

- Joined the Society of Manufacturing Engineers (SME), where participation in technical communities focused on process optimization and machinery upgrades.

- Attended annual training sessions hosted by the International Facility Management Association (IFMA), with a focus on advanced maintenance management.

- Affiliated with the National Institute for Metalworking Skills (NIMS), actively contributing to discussions on tooling certifications and maintenance best practices.

- Earned the Certified Maintenance & Reliability Professional (CMRP) designation through [Training Provider], contributing to the standardization of maintenance logs.

- Member of the Reliability Engineering Association, participating in webinars and meetings focused on predictive maintenance strategies.

- Active participant in local chapter meetings of the American Materials Handling Society (AMHS), collaborating on innovations in supply chain optimization.

- Member of the Society of Maintenance & Reliability Professionals (SMRP), attending industry conferences to stay updated on current maintenance trends.

- Participated in the Maintenance Planning and Scheduling Certification Program, achieving certification after [Number] years of experience in the field.

- Active member of the American Society of Mechanical Engineers (ASME), participating in local chapter events and collaborating on equipment reliability projects.

- Affiliated with the International Organization for Standardization (ISO) auditors, focusing on [Certification] compliance in production environments.

Certifications

- PLC Programming Certification - Siemens/Allen Bradley

- Hydraulics and Pneumatics Certification - [Organization]

- Professional Engineer (PE) License - Mechanical [State]

- Certified Welding Inspector (CWI) – American Welding Society (AWS)

- ISO 9001:2015 Internal Auditor Certification – [Organization]

- Certified Production Technician (CPT) – Manufacturing Skill Standards Council (MSSC)

- Blueprint Reading and Technical Drawing Certification, [Organization]

- Root Cause Analysis Certification - [Organization]

- Certified Industrial Maintenance Mechanic (CIMM) - National Center for Construction Education and Research (NCCER)

- Six Sigma Green Belt Certification – [Organization]

Resources

Rocket Resume has the tools to generate the CV to land your dream job

Generate your CV professionally with Rocket Resume

Use our recruiter-approved suggestions for free

Search and browse CVs

Use these examples to get started