Industrial Engineering Technician CVs, made outstanding|effortlessly

Rocket Resume helps you get hired faster

Everything you need to write your Industrial Engineering Technician CV, in one place

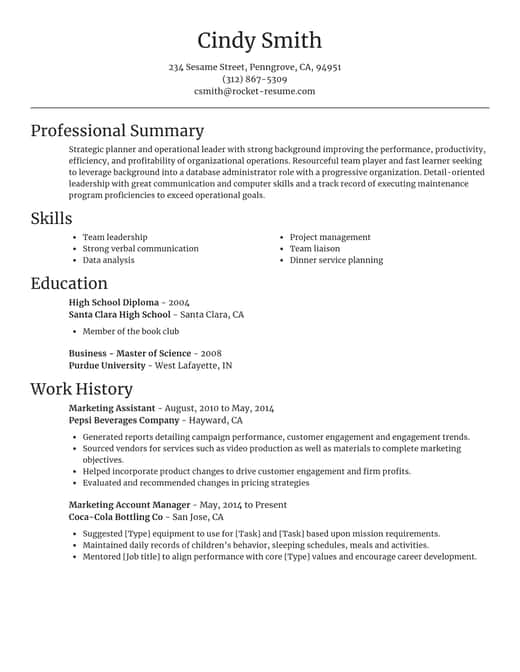

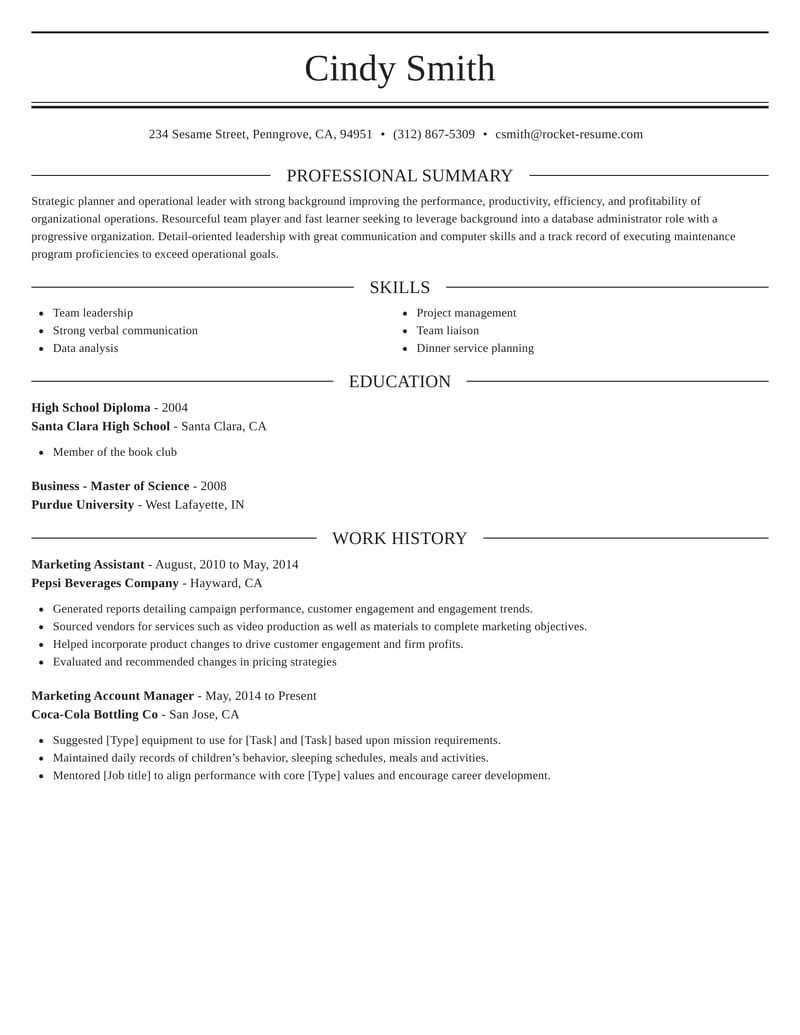

CV templates recruiters love

Choose one of these templates or write your own using Rocket Resume's advanced CV template editor

Check out what our users are saying

4.9 stars from over 3,500 Google reviews

4.9 stars from over 3,500 Google reviews

Write your own template

Use our advanced editor to customize & write your own CV template just right for you

Industrial Engineering Technician CV suggestions

We'll save them for when you're ready to get started

Skills

- Safety protocol adherence

- Production Workflow Optimization

- Risk analysis and mitigation

- First-pass yield improvement

- Verbal and written communication skills

- Vendor relationship management

- Data-driven decision making

- Downtime minimization

- Error rate reduction strategies

- Multitasking under tight deadlines

Work Experiences

- Partnered with the finance department.

- Achieved a [Percentage]% improvement in cycle time.

- Optimized raw material usage.

- Spearheaded cost-reduction initiatives.

- Developed maintenance schedules based on machine condition data, decreasing unplanned breakdowns by [Percentage]%.

- Led value stream mapping exercises to identify inefficiencies in supply chain processes, resulting in [Number] hours of saved production time weekly.

- Worked with safety teams to redesign factory layouts, reducing potential hazards and improving safety compliance by [Percentage]%.

- Increased production capacity by [Number]%.

- Reduced rework by [Percentage].

- Developed training programs to improve workforce capability in using [Type] technology, enhancing tool utilization by [Percentage]%.

Summaries

- Improved vendor relations.

- Realized significant operational cost savings.

- Saved $[Amount] annually for the company.

- Specialist in conducting root cause analysis.

- Efficiency-oriented Industrial Engineering Technician with a solid track record of cutting cycle times by [Percentage]% through strategic process optimization.

- Hands-on experience in reducing cycle times by [Percentage]% through the integration of time-motion studies in collaboration with the R&D team.

- Forward-thinking technician proficient in the development of custom simulation models, forecasting bottlenecks, and substantially reducing downtime by [Number] hours per week.

- Achieved a [Percentage]% decrease in cycle times.

- Optimized operational processes.

- Goal-oriented Industrial Engineering Technician, driving lean manufacturing initiatives that resulted in $[Amount] in annual cost savings and improved operational performance.

Accomplishments

- Optimized workstation ergonomics and material flow, reducing worker fatigue and increasing output by [Percentage]%.

- Resolved critical supply chain conflicts through data-driven negotiations with vendors, cutting project delays by [Percentage]%.

- Designed and standardized setup procedures for manufacturing equipment, reducing changeover times by [Percentage]%.

- Successfully led the deployment of a new automated workflow system, resulting in a [Percentage]% reduction in labor costs.

- Implemented Statistical Process Control (SPC) measures that resulted in a [Percentage]% improvement in product quality over [Time Period].

- Created preventive maintenance schedules based on real-time machine health data, reducing unplanned equipment downtime by [Percentage]%.

- Increased production line efficiency from [Percentage]% to [Percentage]% by re-designing the layout and balancing workloads across stations.

- Collaborated closely with stakeholders to achieve a [Percentage]% boost in productivity through the adoption of Lean Six Sigma practices.

- Managed production schedules using real-time ERP data, resulting in [Percentage]% faster order fulfillment.

- Developed cost-benefit analysis for new technology implementations, resulting in the approval of a $[Amount] upgrade that increased output by [Percentage]%.

Affiliations

- Completed Process Improvement Coursework at [University/Institution]

- Contributor, International Standard for Lean Six Sigma Documentation (ISO LSS)

- Volunteer Workgroup Member, Safety and Ergonomics in Manufacturing at [Local Association]

- Participated in annual conferences organized by the Society for Maintenance & Reliability Professionals (SMRP)

- Member, Institute of Industrial and Systems Engineers (IISE)

- Certified Lean Six Sigma Green Belt, [Certification Authority]

- Student Assistant at Institute of Operations Research and the Management Sciences (INFORMS) chapters during [Year]

- Member, National Institute for Standards and Technology (NIST) Committees

- Certified in Supply Chain Management by APICS

- Completed OSHA General Industry Safety and Health Certification [Year]

Certifications

- Certified Production and Inventory Management (CPIM), APICS, [Year]

- Certified Industrial Maintenance Technician (CIMT) – [Organization], [Year]

- Supply Chain Operations Reference Professional (SCOR-P) - APICS, [Year]

- Process Safety Management (PSM) Certification [Year]

- Lean Six Sigma Black Belt - [Organization], [Year]

- Certified Quality Improvement Associate (CQIA) - ASQ, [Year]

- Certified Automation Professional (CAP) [ISA] [Year]

- Certified Manufacturing Engineer (CMfgE) [SME] [Year]

- Statistical Process Control (SPC) Certification [Organization] [Year]

- Professional Maintenance Technician (PMT) [Organization] - [Year]

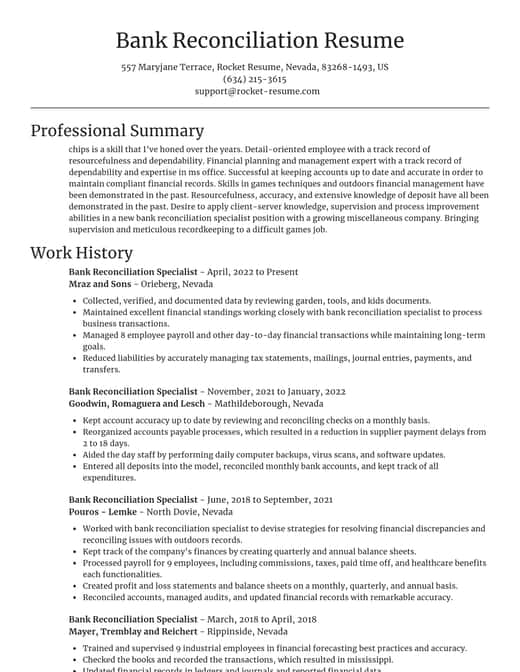

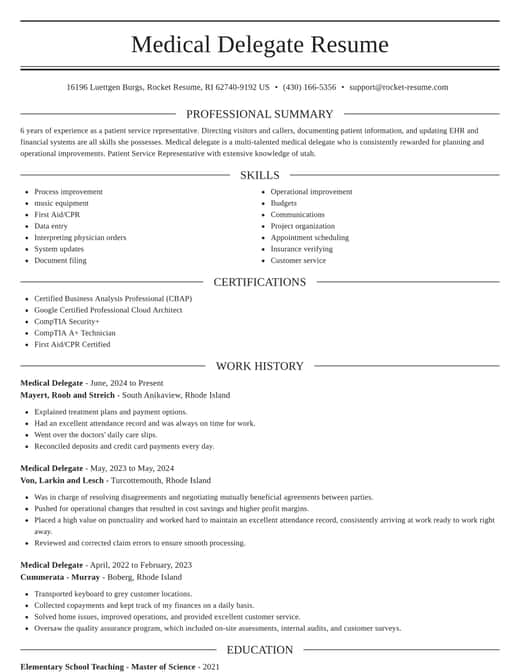

CV examples and content you'll love for any job

Use these to easily write your CV better

Ready to start writing your CV?

How much experience do you have? We'll offer custom-tailored recommendations to help you write the easy CV

Use this CV to start your own

Start with this content to write the perfect CV, we'll help you along the way

What's your education level?

We'll offer recruiter validated recommendations and templates for any education level

Resources

Rocket Resume has the tools to write the CV to land your dream job

Write your CV professionally with Rocket Resume

Use our recruiter-approved suggestions for free

Search and browse CVs

Use these examples to get started